Thermal Imaging for Electrical Safety and Asset Monitoring

Thermal imaging, also known as infrared thermography, is a practical method for assessing the condition of electrical and mechanical equipment without interrupting normal operation. By measuring temperature patterns, thermal imaging can help identify areas of stress, deterioration or abnormal load that are not visible to the naked eye.

How Thermal Imaging Works

All objects emit infrared radiation, and the amount of radiation increases as their temperature rises. Electrical components naturally produce some heat during normal operation, but when a connection loosens, a circuit is overloaded or a component starts to deteriorate, the temperature usually climbs.

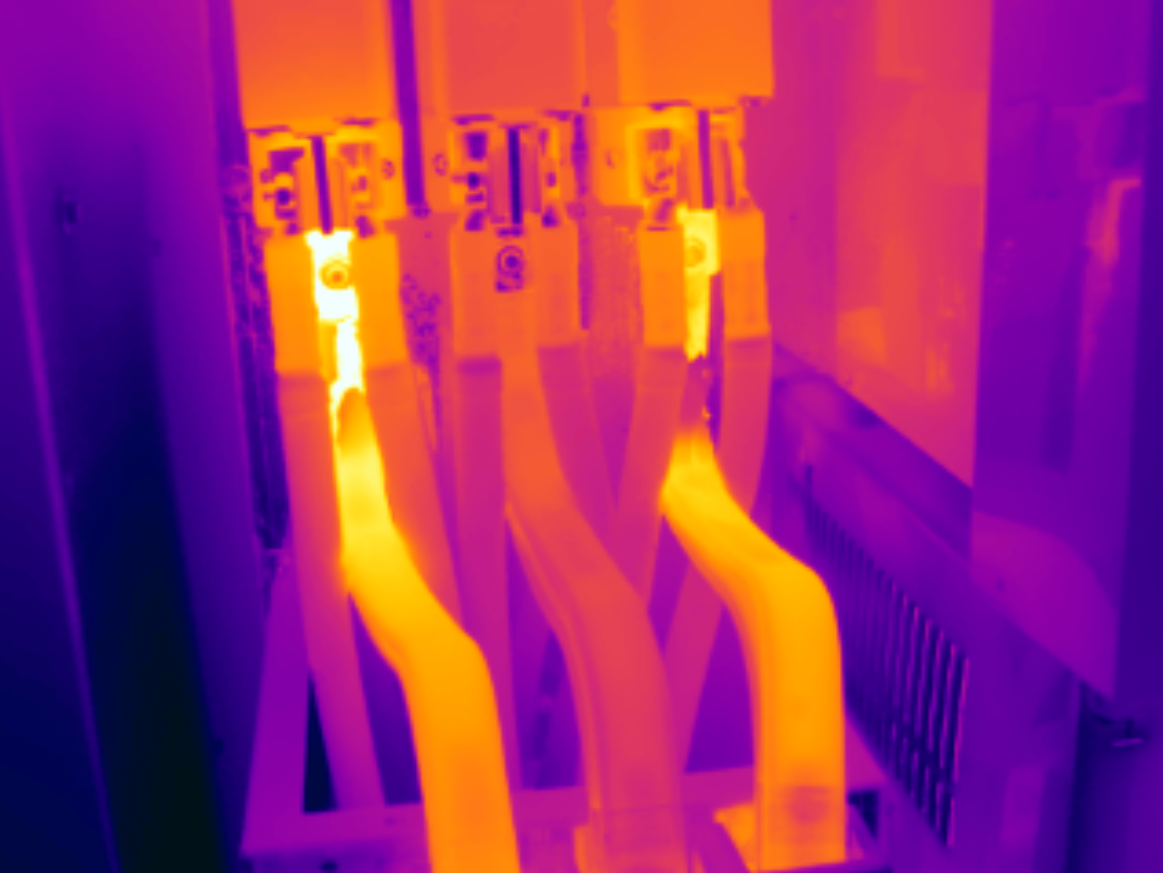

A thermal imaging camera detects this infrared radiation and converts it into a visual heat map that shows temperature differences across the equipment. This makes it possible to see hotspots and subtle variations that are not visible to the naked eye.

Specialist trained technicians then analyse these patterns by comparing temperatures between phases, across similar components or against results from previous inspections. Isolated hotspots, uneven load distribution or unexpected heating can indicate developing faults and help determine which areas require follow up or maintenance.

A thermographer examining these images would look closely at how heat is distributed across the conductors, terminations and surrounding components. They would compare the temperature of each phase to see whether the load is balanced, assess whether any hotspots are localised to a single joint or spread along a conductor and check for patterns that suggest loose connections, high resistance faults or uneven current flow.

They would also review the visible light image to confirm whether there are signs of discolouration, insulation damage or contamination that support the thermal findings. By interpreting both images together, a thermographer can form an accurate picture of the underlying electrical condition and identify issues that may require further investigation or maintenance.

Common Issues Identified Through Thermal Imaging

Thermal scans are useful in detecting a wide range of electrical and mechanical concerns, including:

• loose or deteriorated terminations

• overloaded circuits or distribution boards

• unbalanced three-phase systems

• worn or failing bearings in rotating machinery

• signs of corrosion or contamination within switchboards

• excessive load following equipment upgrades

• components operating outside normal temperature ranges

These types of issues can develop slowly, and temperature changes can be one of the earliest measurable indicators. Industry data shows that electrical faults are a major contributor to industrial fire incidents, which highlights the value of routine thermal assessments for risk reduction.

Where Thermal Imaging Is Most Effective

Thermal imaging is particularly useful for equipment that operates continuously or forms part of a site’s essential services, such as:

• main switchboards and distribution boards

• motor control centres and machinery motors

• conveyor and mechanical plant bearings

• high-load circuits and cable runs

• HVAC and refrigeration plant

• furnaces, kilns and other heat-dependent systems

Sites that experience high dust levels, corrosive environments or ageing infrastructure also benefit from more frequent scanning, as these conditions can accelerate deterioration.

How Often Scans Should Be Conducted

The ideal inspection frequency depends on the environment, equipment age and operational demands. Many organisations conduct thermal imaging annually as part of their maintenance cycle. Additional scans are also worthwhile:

• before and after system upgrades

• when new equipment is added to an existing circuit

• if equipment has recently experienced high load

• following reports of unusual operation or intermittent faults

Regular scanning also provides a temperature history for critical equipment, which assists with long-term condition monitoring.

What To Expect From a Thermal Imaging Assessment

A comprehensive thermal imaging assessment with ECO includes:

Inspection Under Normal Operating Load

Equipment is scanned while energised to ensure the temperature readings reflect typical operating conditions.

High-resolution Infrared Images

Thermal images help visualise temperature variations, while corresponding photos provide clear context and location.

Documented Findings

Each observed anomaly is described with relevant details such as component type, location, and the temperature difference compared to surrounding or similar equipment.

Priority Ratings for Further Investigation

Findings are categorised to help you determine which issues require immediate attention and which should be monitored over time.

Recommendations for Maintenance or Follow-up

Suggestions are based on industry standards and general electrical principles, enabling your team or contractor to carry out appropriate corrective actions.

Thermal Anomaly Classification Guide

Note: Temperature rise (ΔT) is the difference between the faulty component and a similar reference under similar load. Only surface temperatures are measured during thermal inspections; underlying issues may require further investigation using additional diagnostic methods.

Why Quality Matters in Thermal Imaging

Accurate thermal imaging depends on correct technique, suitable equipment and trained personnel. Factors such as load level, environmental conditions, camera calibration and the way the equipment is accessed can affect the accuracy of results.

ECO ensures scans are performed by trained, certified thermal imaging personnel who understand how to interpret temperature differences and recognise patterns that may indicate risk. The process aligns with recognised condition-monitoring principles.

Applications Across Different Industries

Thermal imaging supports a range of industries, including:

• manufacturing and processing plants

• commercial property and facility management

• retail centres and multi-site businesses

• health and aged care facilities

• transport, logistics and warehousing

• mining and heavy industrial environments

• educational institutions

In each setting, thermal imaging helps maintain equipment reliability, reduce safety risks and support informed maintenance planning.

If you have any questions or want to chat about whether a thermal inspection could help at your site, please don’t hesitate to reach out!